Introduction to stone scanner device

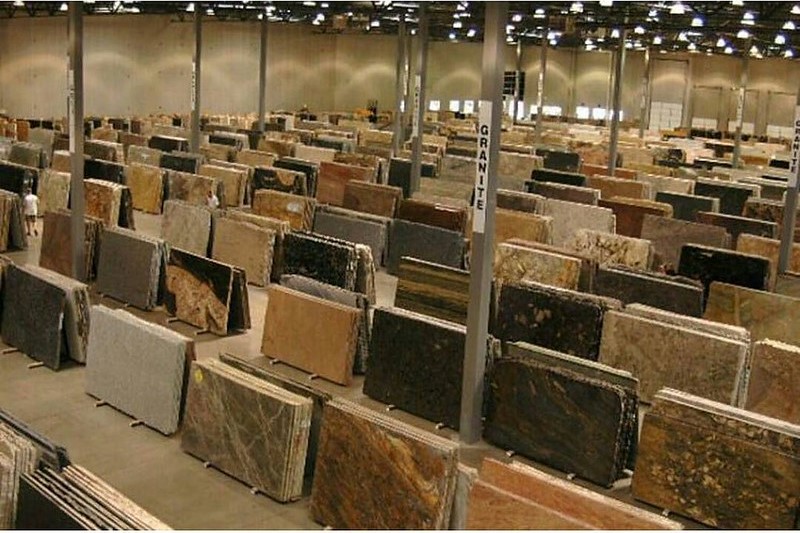

One of the problems that slab stone manufacturers face is displaying the quality and design of slabs to customers. As you may know, after being extracted from the mine, the blocks are transported to factories and cut into smaller dimensions as slabs and are ready for sale. After preparation, slabs are stacked on top of each other in the warehouse. One of the most important marketing parameters for stone sellers in slab form is displaying the product, but due to the dimensions and weight of slabs, displaying them one by one to customers is difficult. Apart from the difficulty and time-consuming nature of this task, continuous movement of slabs may also cause damage.

the slabs arranged in the warehouse

One of the solutions to avoid moving slabs is to produce images of the slabs, create an album of images, and present them to customers so that the customer can calmly examine the products, and the marketing person can effectively convey the necessary information.

But how should we produce images of slabs? Should we hire someone to take pictures of each produced slab with a camera? Will all pictures be acceptable in the long run due to fatigue of the photographer? Will the images have suitable color quality and depth in changing light conditions? How will it be possible to refer to each slab through the corresponding image among thousands of slabs in the warehouse after producing thousands of slab images?

Given the above description, you also agree with us that special and better measures are needed to display produced slab stones.

Information technology companies, such as the Italian company d2technology, the Portuguese company FrontWave, and Chinese companies, are active in improving the production and sale of slab stones. In our country, Iran, which is a major producer of stone and slab products, there is a need for mechanized devices in the production and sale of stones. Unfortunately, access to these devices from foreign countries is possible at a high cost. Also, due to the long distance and difficult access to foreign companies, supporting devices and software are also difficult to obtain.

Zomorod Sanat Asia can be introduced as the first manufacturer of industrial mechanized devices for the production and sale of stone. Currently, the company offers its advanced slab stone scanner device, with a much more affordable price than foreign examples and with proper support, to fellow citizens.

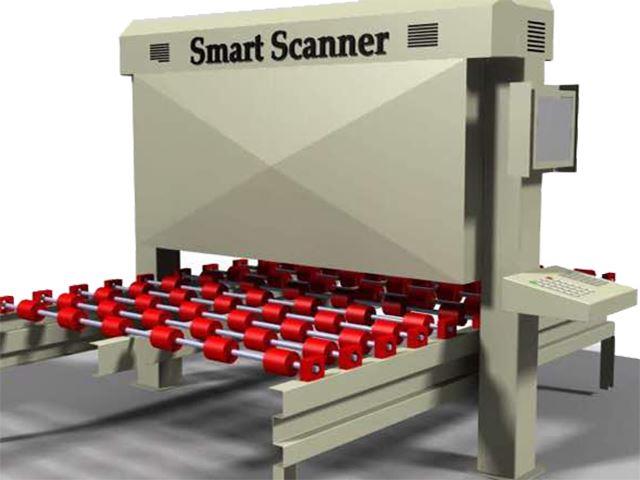

The Zomorod Sanat Asia slab scanner device intelligently and with high quality produces uniform images of each produced slab on the conveyor belt and generates a barcode for each created image, immediately issuing a barcode printing command. The production line operator can then attach the printed barcodes to the slabs and move them to the appropriate location in the warehouse. With the attached barcode, the position of each slab in the warehouse can be identified at any time.

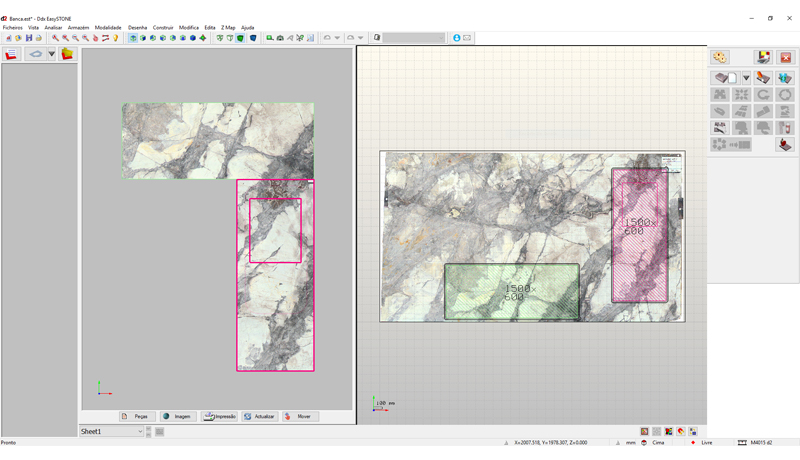

By designing this scanner device and integrated software applications, Zomorod Sanat Asia has been able to create a gallery of its produced slabs, and by presenting this gallery in a suitable way, customer satisfaction in effective product selection can be increased, and products can be sold with minimal damage.

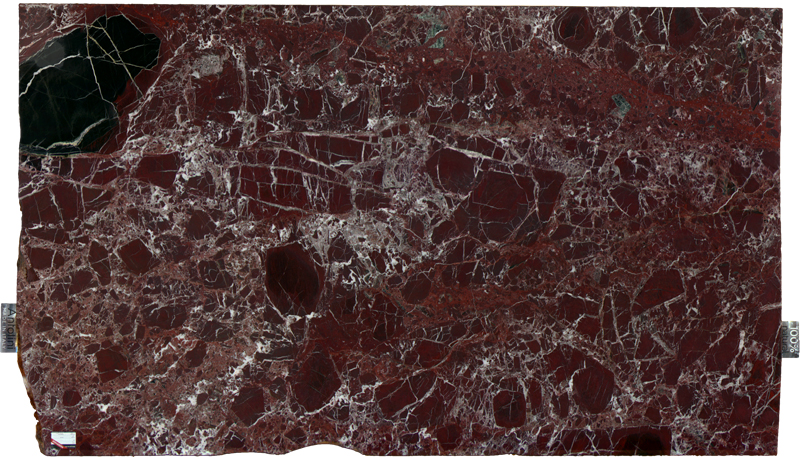

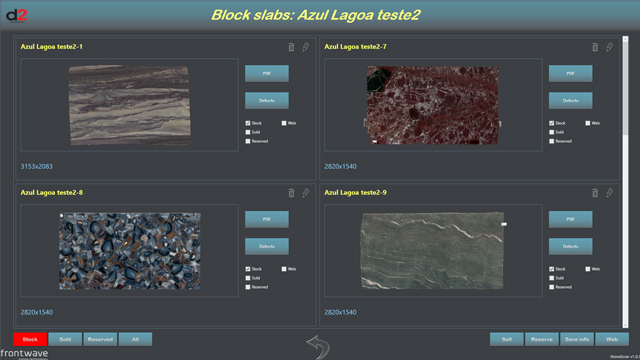

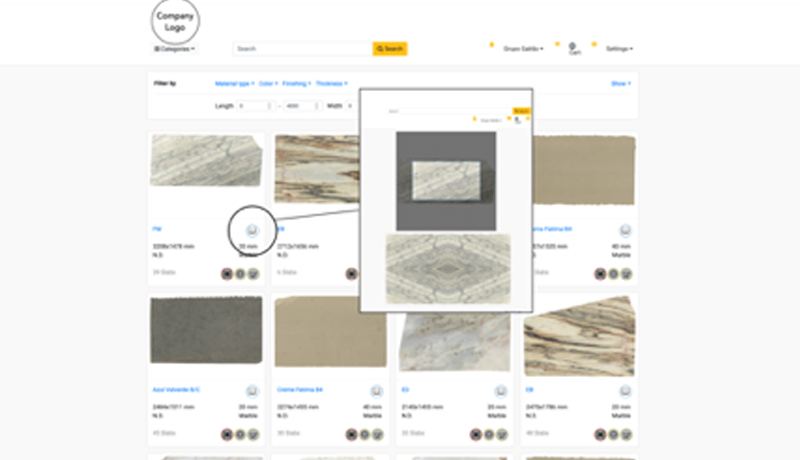

Sample design of a slab pattern

Sample slab gallery

Sample slab image template

According to the needs of the stone slab producer and the different dimensions of the stone slabs, slab scanner devices are divided into the following categories:

- Handheld or portable slab scanner device

- Horizontal fixed slab scanner device

- Vertical fixed slab scanner device

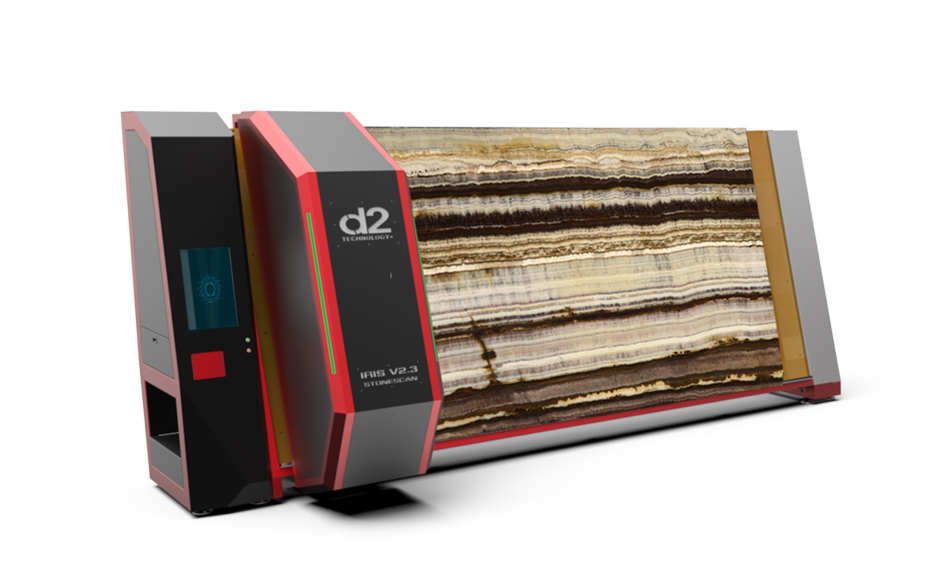

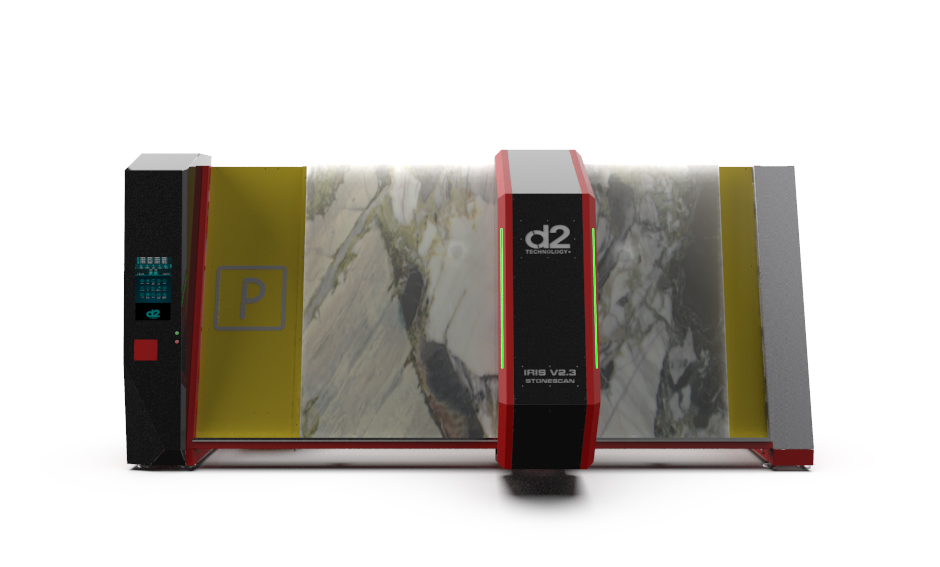

Frontwave Stone Scanning Machine

D2 Scanner

D2 Scanner

Handheld slab scanner devices are mainly used for small-scale applications. With the help of scanner sensors, this device captures the image and saves the scanned image in its built-in memory while the device is moved by hand. After registering the images, the user can use the created images by connecting the device to a computer.

Fixed horizontal or vertical slab scanner devices scan the entire stone slab in two ways: vertical and horizontal. Depending on the production model of the slabs and the pre-existing mechanisms in the stone production factory, the necessary scanner can be selected and used. In the vertical mode, the stone is standing still while the imaging system moves. In the horizontal mode, the camera is fixed and the stone moves on a conveyor belt. In this mode, linear cameras and linear light systems are typically used for scanning. With the help of these types of cameras, scanning operations can be performed on a wide range of dimensions, and the final images are produced with exceptionally high resolution.

Placement of slab scanner device on the production line

Sample image of a scanned slab